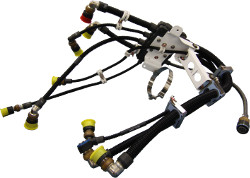

Turnkey Wired Conduit Interconnect Assemblies

Certified factory assembly of point-to-point and multibranch conduit wire protection assemblies for aircraft wheel wells, landing gear and other mission-critical assemblies that require optimal EMI/RFI, mechanical and environmental protection.

Many of the conduit and convoluted tubing systems we fabricate at Glenair are assembled at our factory with tamper-proof crimp ring or solder terminations. User-assembled conduit components offer the convenience and flexibility of do-it-yourself field termination — especially valuable for prototyping of interconnect wire protection systems. But reduced size and weight factory terminated assemblies — from simple point-to-point to elaborate multibranch assemblies — offer the utmost in convenience, value, reliability and durability.

- Labor-saving, ruggedized and lightweight

- Glenair can design, build, terminate — and even pre-wire — turnkey conduit wire routing solutions

- Save space, weight, assembly time and labor cost

- Certified factory assemblers and calibrated tooling for guaranteed performance

- Simple point-to-point or complex multibranch

Application Checklist

Slideshow Presentation

Product Datasheet

QwikConnect

- Factory Terminated Conduit Assemblies / January 2012

Glenair Product Line

Application Examples

|

Expertise in Wired Conduit SystemsGlenair’s expertise in wired conduit systems extends from simple point-to-point jumpers to complex multibranch assemblies (right) as well as turnkey integrated systems and LRUs with flexible conduit interconnect cabling. |

|

Conduit / Integrated Junction Box Aerospace Assembly |

|

Complex Multibranch Fighter Jet Electrical Wire Conduit Assembly |

|

Lightweight, Halogen-Free Rail Industry Wire Conduit Assembly |

|

Crush-Resistant Commercial Aerospace Metal-Core Conduit Assembly |

|

Multibranch Demo Assembly

|

|

Turnkey Integrated Box Assembly and Wired Polymer-Core Interconnect System

|