BLQ ENV-Test: IEC Qualified Laboratory, Inspection, and Measurement Services

ISO 9001 and EN 9100 Registered; Comprehensive Test Plans, Reports, and Documentation IAW Customer Requirements

ISO/IEC 17025

Environmental testing, consisting of the complete range of mechanical, electrical and environmental stress factors that affect electronic equipment, cabling, and systems is now available from BLQ ENV-Test, Glenair's IEC/IECQ certified independent testing laboratory, offering accelerated lead times — from initial quoting to final test report delivery.

- Mechanical / dynamic testing for both electrical and fiber optic components, subsystems, and wiring harnesses

- Automatic testing of harnessing with scientific root cause analysis

- Fast turnaround on quotes and testing services

- Decades of experience

- Unique expertise in high-voltage (partial discharge) testing

- Professionally prepared test reports supplied for every project

- Ample in-house resources for both small and large-scale equipment test plans

Environmental Test Laboratory

BLQ ENV-Test: IEC Qualified Laboratory, Inspection, and Measurement Services

ISO 9001 and EN 9100 Registered; Comprehensive Test Plans, Reports, and Documentation IAW Customer Requirements

ISO/IEC 17025

|

Electrical TestsElectrical / EMC Testing services cover the complete range of performance requirements for interconnect cabling and electronic components. Glenair brings years of EMC design engineering experience into the testing process, ensuring equipment under test is always correctly fixtured and prepared for the most accurate results. Available Tests:

|

|

Ethernet / Optical FiberLight measurement, to measure the main luminous features of our lighting products for railways, such as headlights, tail-lights, traffic lights, and other onboard or trackside lighting devices. Inside this dark room we are able to measure luminous flux (lumen), luminous intensity (candle), chromatic coordinates (X,Y), color rendering index (CRI), color temperature (CCT), the spectral chart and the angular distribution of the light. |

|

Environmental TestsTemperature and Humidity Testing is performed using industry-standard and IEC accepted practices of temperature cycling and humidity exposure. New and high-quality testing equipment ensures accurate results. Available Tests:

Accelerated Harsh-Weather Testing is performed to ensure components under test meet qualification requirements for galvanic corrosion and resistance, resistance to solvents, and S02. Available Tests:

|

|

Mechanical / Dynamic Testing / LeakageControlled vibration and shock testing ensures electrical and electronic components can withstand specified forms of dynamic stress encountered during operation and shipping. Available Tests:

|

|

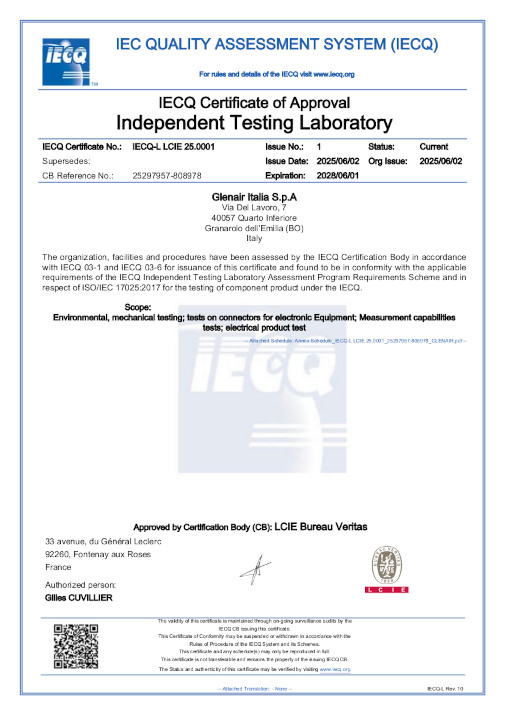

Glenair Italia TestLab ISO/IEC 17025 CertificationThe organization, facilities and procedures have been assessed by the IECQ Certification Body in accordance with IECQ 03-1 and IECQ 03-6 for issuance of this certificate and found to be in conformity with the applicable requirements of the IECQ Independent Testing Laboratory Assessment Program Requirements Scheme and in respect of ISO/IEC 17025:2017 for the testing of component product under the IECQ.

|

Inspection & Dimension: Measurement Solutions Capabilities

- Accuracy

All our instruments are calibrated and evaluated for the most accurate measurement of your components - Flexibility

We measure and report on all components or just a single characteristic - Capabilites

From calibration of customer's gauge tools to the design and manufacture of specialized gauges or fixtures.

Reference

|

Inspection RubberWe have all the instruments to make a characterization of rubber materials: formulation (FTIR), density, hardness, mechanical propriety, and electrical propriety. |

|

Inspection PlatingOur chemical plating lab can analyze your coating and help to ensure the correct formulation of the galvanic bath. |

|

Inspection HarnessOur harness final inspection guarantees fast and accurate testing of your wire harnesses with the latest automatic test equipment. |